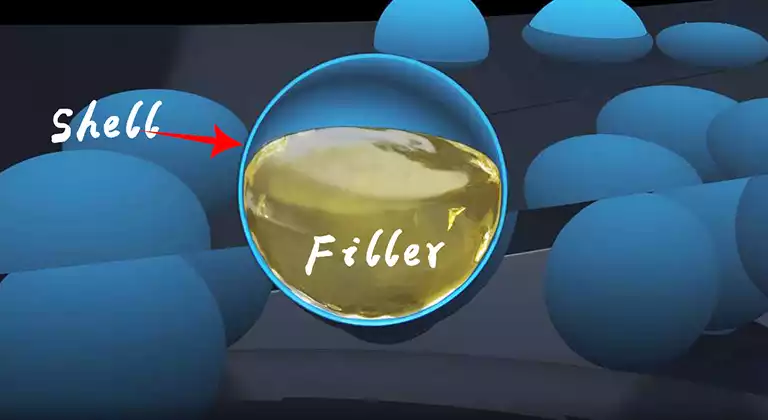

Microencapsulation is the process that encase small particles or droplets in polymer coatings, which are intended for storage, delayed release and protection of filler.

A common method of making microcapsules is solvent dehydration: the filler is added to a gelatin solution and then a hydrophilic substance is added to absorb water molecules near the filler. The gelatin then precipitates and covers the filler surface. Another common method is spray drying: the material for capsule is made into a solution and then its filler is added to make a suspension; it is sprayed into evaporation chamber and contacts with hot air. The solvent can evaporate quickly within a few seconds due to its large surface area. At this time gelatin forms a thin film to cover the filling material.

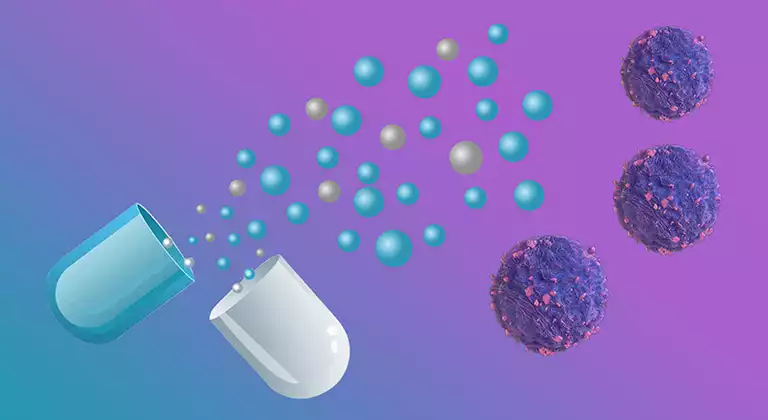

Compared to traditional therapeutic methods, microencapsulated drugs have lower doses, lower side effects and longer lasting effect. For example, anti-cancer drugs in gelatin microcapsules are released slowly and uniformly to keep their concentrations stable in the blood over a long time. However, the traditional drugs have too large concentrations in initial phase resulting in greater side effects, and too small concentrations in end phase leading to poor potency. Microcapsules can also cooperate with magnetic particles for targeted therapy: they gather around tumor to destroy it under the magnetic field. Its biocompatibility, biodegradability and the stable gel structure make gelatin an ideal material for microcapsule.

It is also widely used in the food industry. It is used to encapsulate spices and essential oils to insulate them from air, and effectively prevent oxidation, volatilization and dampness during storage. Gelatin forms a stable gel structure that covers the surface of additives to avoid their reaction with food. Some additives that are unstable under acidic conditions can be used in foods with low PH after microencapsulation.

Owing to its various advantages, the field of application is widening. Since 1954, when the first product (carbonless copy paper) was developed, microencapsulation has been widely used in medicine, pesticides, food, dyes, and textiles.